Introduction

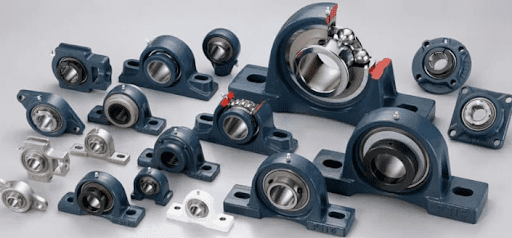

Indian pillow block bearings have come a long way where pricing and quality are no longer poles apart. The industry has grown silently but steadily over decades of industrial practice, smarter sourcing and leaner production systems. While global buyers used to view India as only a low-cost option, the narrative has shifted to value, consistency and reliability. That’s what makes pillow block bearings India a strong proposition today.

A Domestic Manufacturing Base Built on Depth, Not Hype

India’s bearing ecosystem didn’t appear overnight. It was built piece by piece through decades of metallurgy experience, machining know-how, and a culture of industrial problem-solving. This depth shows up in the way factory floors operate. Most large manufacturers aren’t dependent on imported components; they control casting, machining, heat treatment, and assembly under one roof. That tight control keeps variations low and allows them to deliver uniformity across batches.

This stability matters more than marketing claims. Industries that operate in harsh and unpredictable environments — mining, cement, material handling, process factories — cannot afford bearings that behave differently with each delivery. The domestic manufacturing base has learned this the hard way over the years, and that learning curve has turned into a genuine competitive advantage for pillow block bearings India in both reliability and availability.

How India Keeps the Cost Curve Lean Without Cutting Corners

The cost-effectiveness does not come from shortcuts. It comes from a combination of predictable factors that manufacturers have learned to optimize. One is local sourcing. Most of the cast iron and steel used in housings come from well-established foundries within the country. This keeps both transportation and procurement overheads low. Another is workforce skill. Indian machinists, grinders, and assembly workers have been producing bearing components for generations. The skill passed down over time translates into fewer rejections, tighter tolerances, and smoother production cycles — all of which reduce wastage, which eventually lowers cost.

A large part of the cost advantage comes from deliberate process decisions. Production lines rely on modular setups that can switch between sizes quickly. Machines are maintained for longevity, not speed alone. And quality checks are integrated throughout the line, so rejects are caught early instead of snowballing into expensive shutdowns. This discipline allows manufacturers to offer competitive prices without compromising the metal quality or the fit-and-finish that bearings must deliver to survive tough industrial environments.

Why Quality Holds Up Even at Lower Price Points

Cost-effective does not mean fragile. The engineering behind pillow block bearings is straightforward but unforgiving. The bore alignment must be precise, the sealing must hold up against dust and moisture, and the housing must absorb vibration without cracking. Indian manufacturers take these fundamentals seriously. Most housings are cast with close-grain structures to resist deformation. The finishing of the bearing seats is done with high repeatability, ensuring proper fitment of inserts and reducing stress points.

Lubrication channels and seals are designed around real-world conditions rather than textbook specifications. Many Indian-made units use grease pockets that hold lubrication longer, especially useful in environments where maintenance isn’t always punctual. The bearings themselves — typically deep groove or self-aligning types — are produced with consistent hardness and surface smoothness to reduce friction and extend running life.

This emphasis on fundamentals explains why a lower price doesn’t translate into lower endurance. It simply means manufacturers have become efficient at producing what industries actually need, without dressing the product with unnecessary features that inflate price but offer marginal value.

The Advantage of Practical Designs Over Over-Engineered Imports

In many imported bearings, cost increases because of design features tailored for very specific industrial climates. Indian bearings, however, are built around the realities of typical usage: dusty plants, uneven shafts, fluctuating loads, and inconsistent maintenance routines. This practicality drives the design philosophy. The self-aligning capability in many units compensates for common installation irregularities. Grease-lubricated bearings with proven sealing arrangements prevent early contamination failures. The housings are built thick enough to tolerate vibration but not excessively chunky to inflate material costs.

This balance is a major reason pillow block bearings India win in environments where over-engineered products offer little everyday benefit. Instead of offering ten features customers never asked for, Indian units offer the three or four that genuinely determine uptime.

Reliability That Comes from Consistency, Not Marketing

For industrial buyers, consistency is sometimes more valuable than spec sheets. A bearing that performs the same way across multiple orders saves more downtime than a bearing boasting theoretical numbers. Indian manufacturers understand this expectation. Most factories run strict batch-control systems. Heat treatment cycles are monitored carefully. Machining lines follow tried-and-tested sequences that keep dimensions stable. Final checks measure not only size but also noise, vibration, and rotation smoothness.

Because the processes are disciplined and repeatable, users get predictable performance. And predictable performance is the backbone of reliability. When a plant knows what to expect from a bearing, it can schedule maintenance smarter, plan inventory better, and reduce unplanned shutdowns. This is how quality becomes a practical value, not a marketing phrase.

Customization That Cuts Waste Instead of Adding Cost

A major strength of Indian manufacturers lies in their willingness to produce small variations without inflating price. Many factories can adapt bore sizes, grease arrangements, locking mechanisms, and sealing types without overhauling entire production lines. This flexibility allows industries to get exactly what their application demands — not a one-size-fits-all unit that partially works and partially wastes energy.

Customization also helps avoid over-specification, a common issue when buyers import bearings based on catalogue assumptions rather than real field conditions. When the product matches the requirement precisely, material costs stay low, power consumption stays sensible, and bearing life stretches further. This is another subtle reason pillow block bearings India offer a better return on investment.

The Long-Term Value That Outweighs the Price Tag

Even though Indian pillow block bearings are priced competitively, their real value shows over the long term. With stable metallurgy, good sealing, sturdy housings, and repeatable fitment, they tolerate conditions that often strain imported alternatives. They reduce sudden breakdowns caused by misalignment or premature wear. They require minimal lubrication top-ups. And they maintain smooth rotation even as operating conditions become unpredictable.

The result is a lower cost per operating hour — the metric that truly matters for industries running high-utilization machinery. The initial price matters, but the long-term reliability matters more. This combination of fair pricing and durable performance is what makes pillow block bearings India such a compelling choice for industries aiming for dependable uptime.

Check the latest technology insights and Business strategy directly at https://techbizflow.com.

Conclusion

Indian pillow block bearings didn’t become cost-effective by chance. The edge comes from factories that understand the rhythm of real industrial work—tight tolerances, harsh dust, unpredictable loads, and machines that simply cannot afford downtime. When manufacturers focus on fundamentals instead of flash, the result is hardware that holds its ground without inflating the price tag.

That’s why pillow block bearings India stand where they stand today: built on disciplined processes, practical engineering, and an industry mindset shaped by decades of doing things the hard way. The combination of sensible pricing and steady, predictable performance is what gives them their pull. And for industries looking for bearings that don’t break budgets or machinery, the Indian-made units remain one of the few options that strike that balance with confidence—not by promise, but by proof.